Explainer | Why there is a global semiconductor shortage, how it started, who it is hurting, and how long it could last

- The shortage was exacerbated by ‘double booking’ from anxious chip buyers, who were concerned about supply chain security amid the US-China tech war

- Beyond consumer electronics, the tight supply has begun to impact China’s giant home appliance manufacturing sector

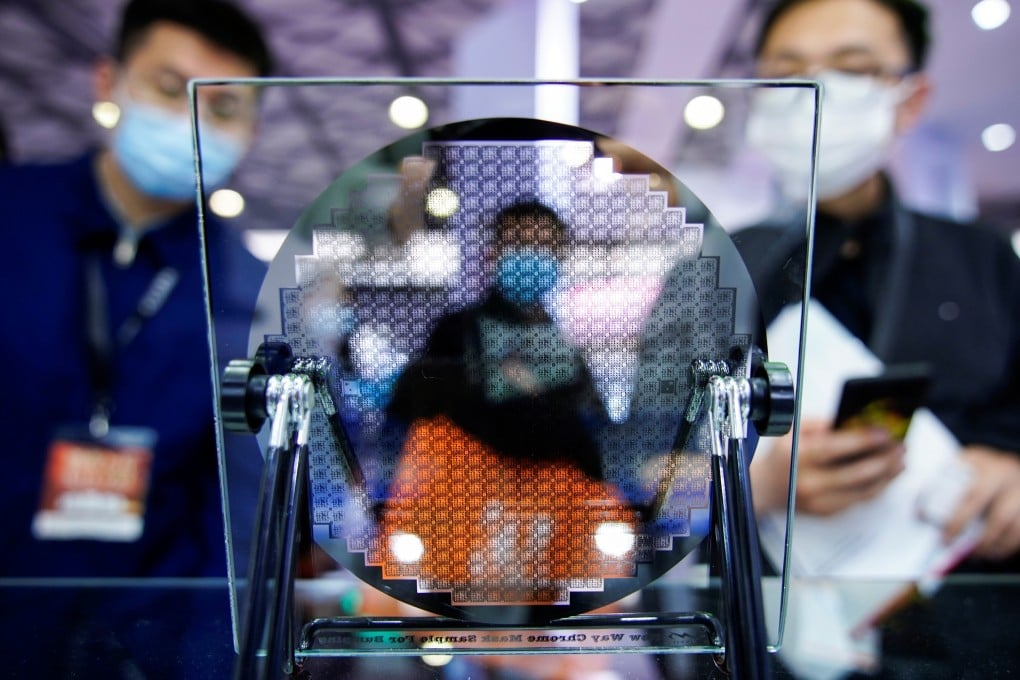

Semiconductors, also known as microchips and integrated circuits (ICs), are essential components in every electronics product, whether it be a simple remote control unit for changing channels on the television, or a supercomputer used to simulate weather patterns.

While chips themselves are resilient, made to handle extreme temperatures, vibrations and other external shocks, the global semiconductor supply chain is relatively fragile, prone to disruptions from natural and man-made shocks.

The supply of chips cannot be turned on and off with a switch. Multibillion-dollar wafer fabrication plants are finely tuned and run 24/7, 365 days a year. Changing the production line for a new chip product can take weeks, if not months, and adding significant new wafer fabrication capacity can take years and billions of dollars.

The car industry’s faster-than-anticipated bounce back after factory shutdowns – when companies cancelled chip orders after incorrectly forecasting lower demand for the rest of the year because of the pandemic – sent semiconductor supply into a downward spiral, creating a shortfall in the tiny electronics across a wide swathe of industries.

The scarcity of ICs is not expected to end any time soon. Experts say it could be two more years before the supply-demand balance is restored.