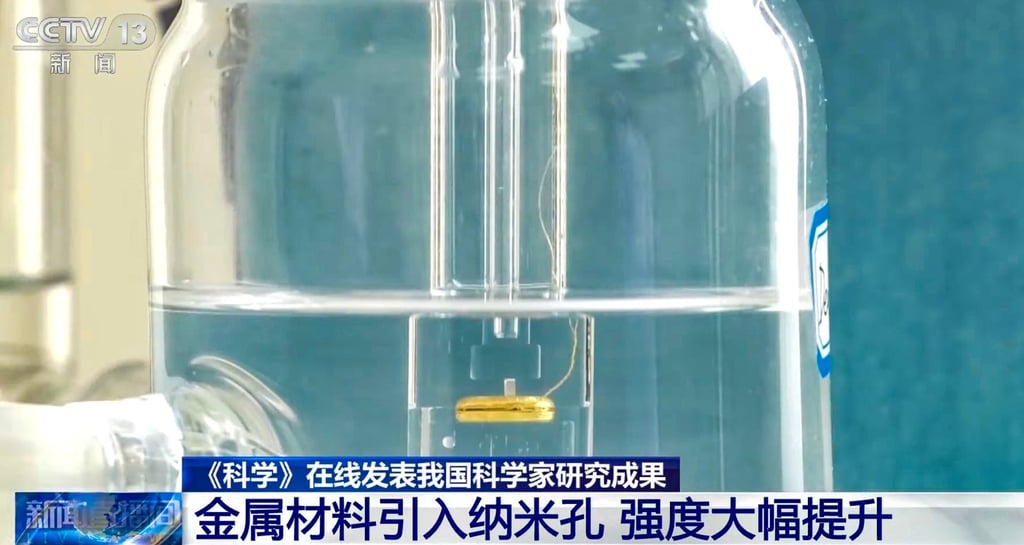

Chinese scientists say they can strengthen pure gold by adding tiny holes

- Nanopores added to precious metal allow it to bear higher loads and maintain plasticity with ‘no extra weight, no pollution’: Science paper

In conventional metal forming methods such as casting, welding and 3D printing, bubbles are seen as significant material flaws and engineers take utmost care to avoid them.

Internal bubbles in metals can lead to strength loss, bubbles at metal junctions can reduce durability and surface bubbles can impair the material’s finish.

However, a team from the Shenyang National Laboratory for Materials Science at the Chinese Academy of Sciences (CAS) found that instead of eliminating these voids, “refining their size and regulating their shape and distribution could not only mitigate their detrimental effects but also offer additional benefits”.

The research, led by Jin Haijun of CAS, was published in the peer-reviewed journal Science on August 8.

“[This] suggests an attractive way to manipulate the properties of solids,” said Brent Grocholski, a senior editor at Science.

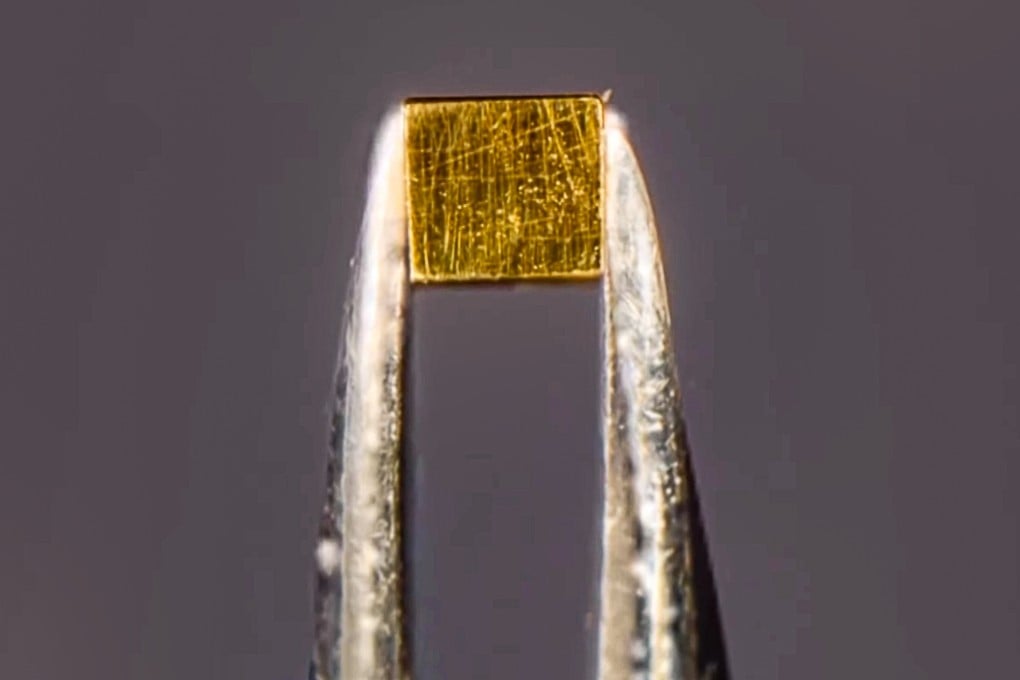

The team used gold as a model material and created uniformly structured porous gold through a de-alloying corrosion process. By compressing and then annealing – or heating and cooling – the metal, they produced a new material filled with dispersed nanopores smaller than 100 nanometres.