How robots are changing the world of high jewellery, from reducing production costs to creating daring new designs – but can AI ever replicate the delicate touch of a human craftsman?

- Italian luxury brand Bulgari celebrated 75 years of its Serpenti series with an installation in Milan by artist Davide Quayola – in which a robot arm gave a live chiselling performance

- ‘Robots fascinate me!’: Hong Kong-based jewellery giant Chow Tai Fook shared a video on its Facebook page in which executive director Adrian Cheng shook hands with a robot

We’re officially in the future, with the jewellery industry the latest to be shaken up by robots that are creating pieces that might not touch a human hand before they are worn for the first time.

While the benefits of automation are significant, including cutting down on production costs and saving time, there are questions as to whether robots can truly replace the human touch needed for the most high-quality pieces.

Still, as the industry continues to face a shortage in manpower, the use of robotics is likely to become more commonplace, particularly when it comes to producing lower-quality pieces. Studios are investing in automation to broaden their manufacturing capacity.

Conventional manufacturing, including of jewellery, is traditionally a labour-intensive process. This creates big challenges in monitoring and managing production, including variations in product types and processes, manufacturing time and scheduling.

The Hong Kong Institution of Engineers has described industrial digitalisation as an efficient solution for improving productivity and resource management through simulation. Potential benefits include a higher worker utilisation rate, reduced production consumption and more efficient production processes.

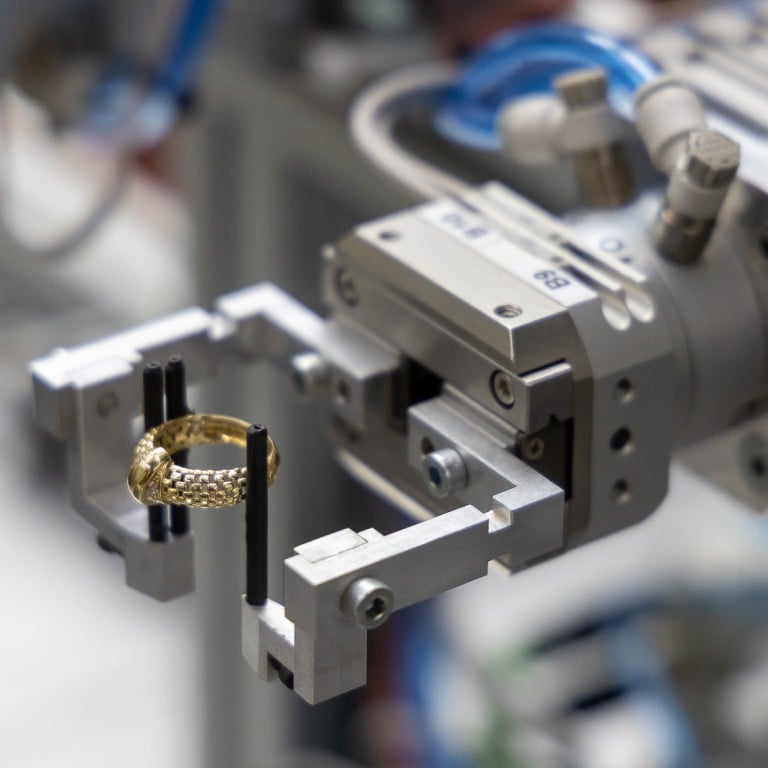

In October 2022, Christian Tse, founder of California-based Christian Tse Designs & Manufacturing, began producing jewellery using a modular robotic system developed by engineering firm Flexible Robotic Environment (FRE).

The system is “the most powerful, flexible and user-friendly jewellery processing system in the world today”, Tse said at the time.

“These new robots will save our clients labour costs, and the automated precision will automatically create a better-finished product for the fine jewellery consumer.

“Robotic polishers allow optimal efficiency and cost savings for the fine jewellery brands we manufacture for.”