Is 3D printing the next big thing in high jewellery? Tiffany & Co., LVMH-owned Bulgari, Boucheron and Boghossian have all embraced the new technology in a world where handcraftsmanship is key

- The luxury jewellery industry is prized for its time-honoured craftsmanship, but more brands are turning to new technologies – like De Beers’ AR that allows clients to virtually ‘try on’ pieces

- Boucheron’s latest Contemplation collection features a stunning diamond necklace designed by an algorithm and Bulgari even launched three high jewellery NFTs in 2022

Boucheron’s forward-thinking Contemplation collection, for example, included an extraordinary necklace that used a mathematical algorithm to suspend diamonds in a cloudlike structure. Contemplation was followed by the maison’s rainbow-inspired Holographique line, influenced by Icelandic-Danish artist Olafur Eliasson and Mexican architect Luis Barragan. A hologram technology pioneered by French aeronautics company Saint-Gobain was used to spray slices of rock crystal with a creative material that makes jewels appear to be changing colour.

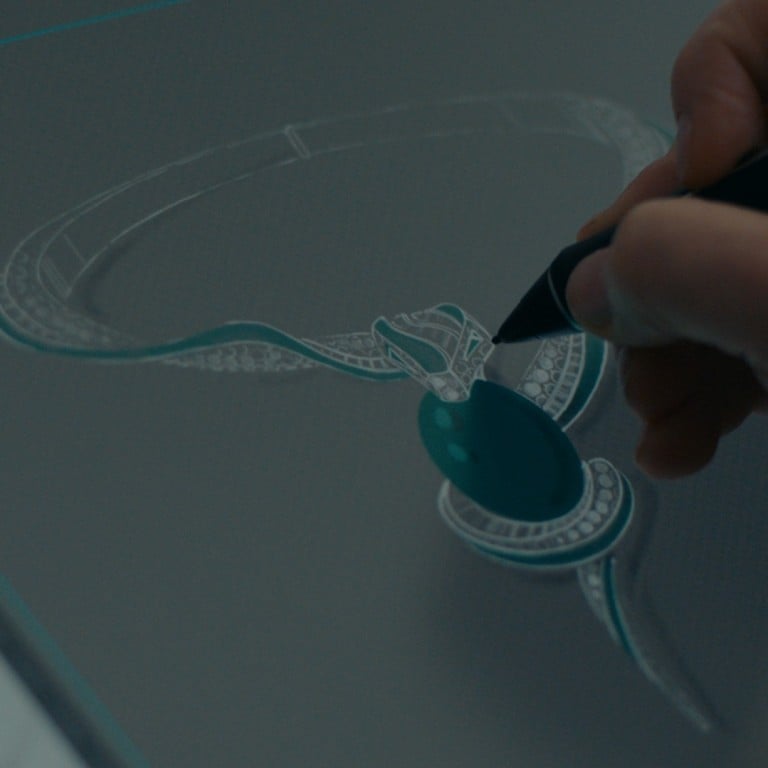

Boucheron isn’t the only high jeweller to develop digital tools that use sophisticated 3D printing. Tiffany & Co.’s workshop in Manhattan is lined with wooden benches from which artisans peer through magnifying glasses to critique prototypes born out of 3D technology.

Then there’s Boghossian, which has long used cutting-edge craftsmanship to create sparklers that defy convention, and has unveiled its innovative Diaphane Mesh creations for 2022. Family-run for six generations, Boghossian claims its brand new gemstone mesh is the thinnest and most flexible ever created.

A masterwork of design, an especially spectacular set of earrings is secured to lobes using a pair of otherworldly opals mottled like marble. The woven mesh is miniaturised until it’s so fine it could be mistaken for transparent, yet the silhouette effortlessly supports a stunning selection of coloured gemstones, hundreds of which are laser-soldered together.