What do real timepiece collectors look for? Watch bridges – and Swiss luxury brands Girard-Perregaux, Corum and MB&F elevate this vital mechanism to an art form

- Girard-Perregaux has upped the game with the 18k rose gold 44mm Tourbillon with Three Flying Bridges – bringing the often-overlooked, vital component to the fore

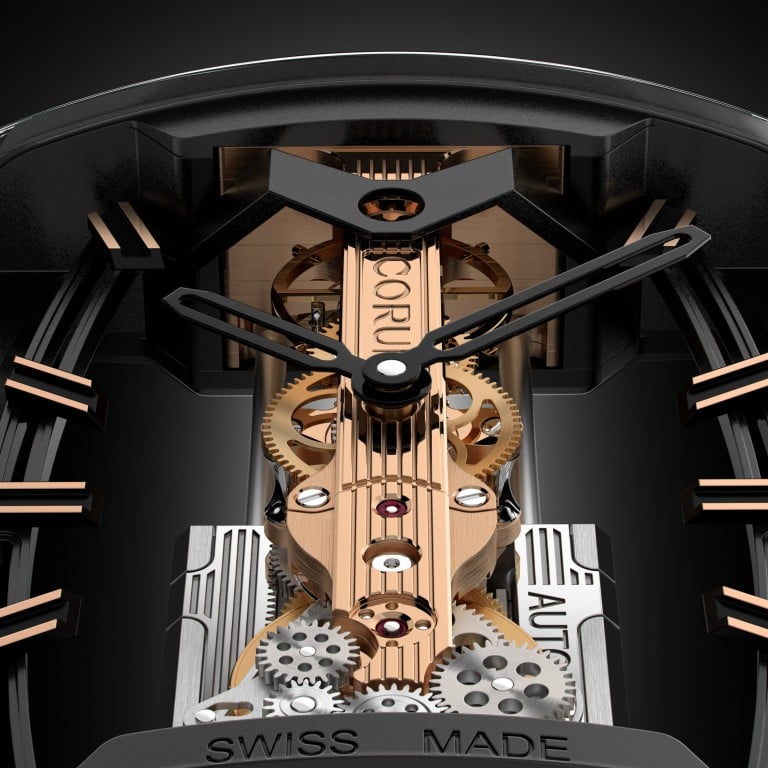

- MB&F’s LM1 and LM2 took inspiration from Jules Verne and the Eiffel Tower, while Corum’s celebrated Golden Bridge was invented by Vincent Calabrese

Quite simply, bridges are essential – and overlooked. “Without bridges you have no movement,” says Clémence Dubois, Girard-Perregaux’s chief marketing officer, hailing the watch movement’s key supporting actors, without which the mechanical story would simply fall apart.

Girard-Perregaux created the Three Bridges, one of the industry’s most coveted designs, 154 years ago. Since then, the symmetrical concept has undergone several stages of evolution – the most radical coming in 1991, when the whole movement was turned upside down in order to showcase the bridges from the front.

And now, the watchmaker, based in the Swiss town of La Chaux-de-Fonds, has upped the game with the new 18k rose gold 44mm Tourbillon With Three Flying Bridges, an extremely skeletonised design which offers the bridges a starring role.

“On this watch the bridges are also the mainplane,” explains Dubois. “They are a continuation of the case, which is essentially two sapphire boxes with a sideband. To give the bridges maximum visibility, there is no bezel, no case back, and the micro rotor is hiding behind the barrel so as not to disturb the view.”

Its curved, contemporary, architecturally inspired execution of the bridges is called Neo Bridges, and they are made in gold, shaped by a five-axis CNC machine and coated with black PVD. Finally, they are chamfered by hand to reveal a shimmer of gold at the angles.

In the spring of 2021, Antonio Calce, former CEO of Girard-Perregaux, took the helm at Greubel Forsey. The company, founded in 2004 and also based in La Chaux-de-Fonds, is famous for its seven ingenious inventions and extremely artisanal approach. Currently around 100 people make only 140 or so timepieces per year.

“All our bridges are outside the box,” Calce says. “It is a big process to decide the right design for a bridge – a process with eight-to-10 people involved, analysing every step of the way. The most difficult to shape is the Handmade 1, which takes 10 hours – and if you look at the Quadruple Tourbillon, there are four bridges, and each of them takes eight hours of handwork to decorate and finish.”

It comes as no surprise that the biggest department in the company is the decoration department. “Usually the movement cost is one-third decoration, one-third production and one-third assembly and adjustment.