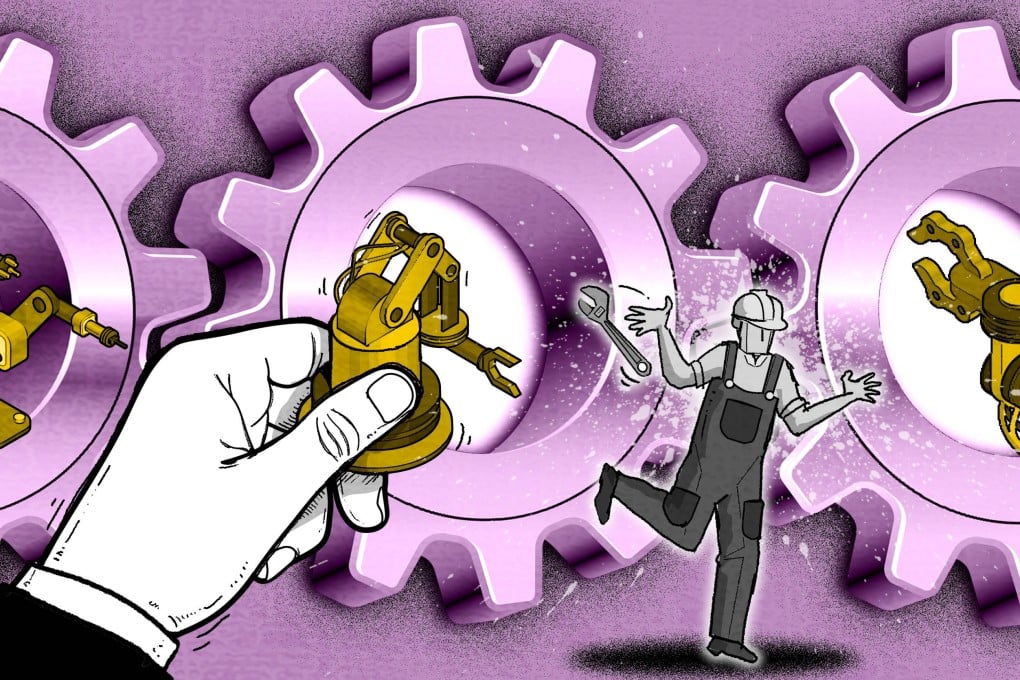

China’s industrial automation efforts give hope to struggling industries, but underlying problems persist

- Pandemic-led export boom, concerns over China’s rapidly ageing society and a desire to save money have all contributed to the trend of replacing workers with machines

- Automation helps upgrade manufacturing and the supply chain, but some say it does little to help boost domestic consumption or address China’s ageing problem

At his family’s small rice factory in Hunan, Zhou Di has invested more than 200,000 yuan (US$31,350) over the past three years to arm it with automation, including machines for sorting and packing.

“All rice-processing factories I know of have been automated, at least partially. Although my family is located in a rural farming village and with only four people, we’re no exception,” said Zhou, who harvests 100 acres of rice a year, yielding about 100 tonnes of the grain. “My parents are close to 60 years old, and automation is what will keep our rice factory running instead of closing down in the future.”

With the large-scale market applications of automation, China has made breakthroughs across a range of technologies, including navigation and optoelectronics, said Luo Jun, chief executive of the International Robotics and Intelligent Equipment Industry Alliance, a government think tank focused on smart manufacturing.

The price for each rice-colour-sorting machine has fallen … That means more SMEs can afford to upgrade their production lines

“In terms of combining artificial intelligence and industrial automation technology, China has been very close to the leading level,” Luo said, adding that China, as the world’s factory, stands to benefit more than other countries from a broader application of automation.